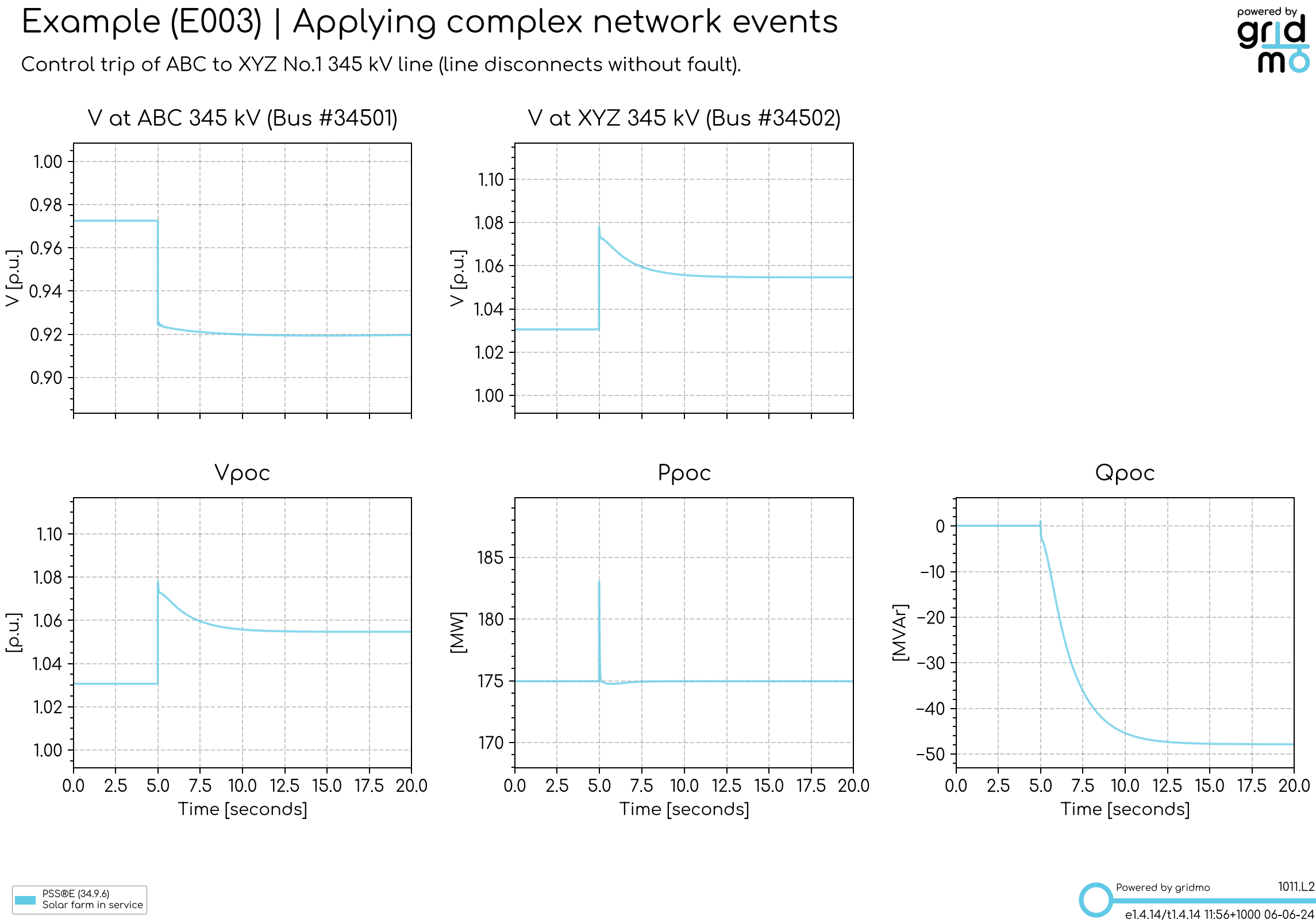

Control Trip

Are you looking for cutting-edge solutions in satellite monitoring, security systems, and logistics, or perhaps seeking to enhance your gaming experience with advanced keybinds? The world is rapidly evolving, and staying ahead demands a keen understanding of sophisticated technological and operational systems that streamline processes, enhance security, and optimize performance.

In the bustling landscape of modern business and daily life, the need for efficient and reliable systems is paramount. From monitoring vast territories with satellite technology to securing homes and communities with advanced alarm systems, the solutions available today are transformative. Further, the evolution of gaming has created an arena where mastering controls and understanding keybinds can significantly impact performance.

This article delves into various aspects of these critical systems, providing a comprehensive overview of the technologies and strategies that define success. We will explore diverse areas, including the operational intricacies of companies specializing in satellite solutions and security systems, as well as the practical application of advanced control mechanisms.

Let's begin by considering the broad array of services offered by companies specializing in satellite monitoring, security, and logistics. A company operating extensively across Argentina offers an impressive range of services. Their expertise includes satellite monitoring, security systems, and logistics, along with home alarm systems, cell signal boosters, flow meters, communication systems, and services tailored to transport operators. Such a wide array of services underscores a commitment to providing comprehensive solutions that meet diverse needs.

Companies specializing in satellite solutions offer a comprehensive range of products, providing crucial services that leverage the latest in technological innovation. Their offerings can include, but are not limited to, real-time tracking, environmental monitoring, and secure communications, serving both public and private sectors.

Another area of interest involves understanding the intricacies of controls, especially in critical systems. Consider the example of the control trip mechanism. This mechanism ensures safe operation by providing solutions and services related to control systems. This could include everything from industrial automation to the management of complex operations. The focus is on maximizing efficiency and security.

Consider the specifics of a control system operating within an industrial environment. The system can face unique challenges, like the harsh conditions and demanding performance requirements. For instance, understanding the effects of a drop in net oil pressure during compressor startup or the proper refrigerant charge levels is essential. The importance of these factors is heightened when considering that the oil pressure control can trigger a trip if the compressor experiences an internal overload.

In such scenarios, the operation of machinery relies heavily on automation and precision. Let's take the example of an industrial control box with specific characteristics, such as those found at Electroswitch, located at 180 King Avenue, Weymouth, MA 02188. Here, the control system must adhere to rigid standards and have fail-safe mechanisms to ensure continuous operation.

Understanding the specific hardware components involved in these control systems is critical. These may be related to various error codes and operational parameters. For instance, hardware fault (HF) trip codes can provide insight into the internal functioning of the drive, often not caused by the user but rather stemming from electrical noise or vibration.

The design and engineering of these systems also address issues like failure. Its well-known that no system is entirely infallible and that failures will inevitably occur. Even with redundant systems such as an uninterruptible power supply, power wires can be cut, fuses can blow, or cables can be damaged. This is why comprehensive planning, risk assessment, and preventative measures are critical in any industrial setup.

Now consider a scenario where a compressor contactor is energized, but the oil safety control registers that the compressor is running and producing oil pressure. This is a potential malfunction that needs to be addressed. Similarly, in complex systems, the availability of last cause of trip LEDs on each control can provide valuable information about the nature of any failures or shutdowns that occur.

The complexity of these systems is further illustrated when we consider the use of three-phase controls, which often have a single, minimum trip level set for all three phases using a single selector. Additionally, the tripping oil itself is generated by a tripping device, and there are separate oil lines for the trip oil to overcome the spring action of the ESV.

In systems, control valves play a crucial role, always running with the amount of oil needed to lift the valve. In gas turbine systems, during start-up sequences, such as at 49% speed, the system may trip due to hardware control failures. In this instance, the system could run normally in the next attempt if the issues is resolved.

Analyzing the specific operating parameters and their impact on the systems performance is essential. Considering the experiences of other users who may have encountered similar alarms can provide valuable insights. For instance, one might look to the OEM (Original Equipment Manufacturer), like Ansaldo, which develops the components that will impact the system.

To access and manage such systems, entering login details is essential. This underscores the importance of security protocols.

Let's now pivot to the discussion of safety and control, specifically focusing on prevention and control measures for slips, trips, and falls. Once potential hazards have been identified through risk assessment, it's essential to implement prevention and control measures to mitigate these risks. This involves a range of strategies, including good housekeeping practices and the installation of safety features.

In many industrial settings, positioning the controls correctly is critical. Consider a scenario where the placement of a breaker is set locally. This allows individuals at the breaker junction box to trip the breaker by closing the control switch (CS). Conversely, switching it to the remote position permits the relays in the control house to trip the breaker, offering versatility in how the breaker may be operated.

The operation of domestic systems, like deep well pumps controlled by a Franklin Deluxe 2HP control box, can also present operational concerns. For instance, if the pump and box are roughly nine years old, occasional issues with the control box, such as blown capacitors, are commonplace. This highlights the importance of regular maintenance and the importance of replacing equipment when needed. The control switch can operate two breaker handles, providing additional safeguards.

The design of control systems often utilizes specialized components, such as an E300 electronic overload relay, which provides detailed control capabilities. These relays are equipped with several features, including low-pressure trip mechanisms and high-pressure trip mechanisms, offering the capacity to reset automatically. The system also incorporates low-pressure and high-pressure lockout functions for extreme conditions.

The control system must continue to operate even after faults or external factors are in place. A well-designed control system can adapt and perform in a wide variety of conditions.

Let's shift our focus to the world of keybinds and controls within the context of gaming, where a deep understanding of key configurations directly impacts gameplay. Mastering the right combinations and controls can significantly enhance a players experience.

The use of keybinds allows for customization and optimization, where players can adapt the game's controls to best suit their play style.

Here is a table which focuses on the specifics of the equipment mentioned in the text, such as the control box and related components, it is tailored for inclusion in a WordPress environment:

| Component | Description | Features | Notes |

|---|---|---|---|

| Franklin Deluxe 2HP Control Box | Control box for a 2HP deep well pump | Manages pump operation, protects against overloads, and typically includes capacitors. | Age of approximately 9 years. Occasional issues like capacitor failures. |

| Capacitors | Electronic components used for energy storage and filtering in the control box. | Critical for starting and running the pump motor. | Prone to failure over time. |

| Pressure Tank | Water storage tank used with the pump system. | Maintains water pressure in the system. | Waterlogged tanks may require replacement. |

| E300 Electronic Overload Relay | Overload relay for protection against electrical faults. | Provides protection against overloads, low pressure, and high pressure. Includes auto-reset and hard lockout functions. | Used for safety and operational control. |

| Control Switch (CS) | Switch for controlling the breaker. | Can be positioned locally (at the breaker) or remotely (in the control house). | Allows for flexible operational control. |

| Breaker Handles | Used in conjunction with the Control switch. | Handle operation of the breaker switch | Ensures proper functionality |

The information presented focuses on specific technical and operational systems, the articles content is suitable for a broad audience interested in practical knowledge and system solutions.